There are two different types of timing belt strength and they are independent of each other. They are tooth shear strength and tensile cord strength. To correctly size a belt, both strengths should be higher than the application strength requirements.

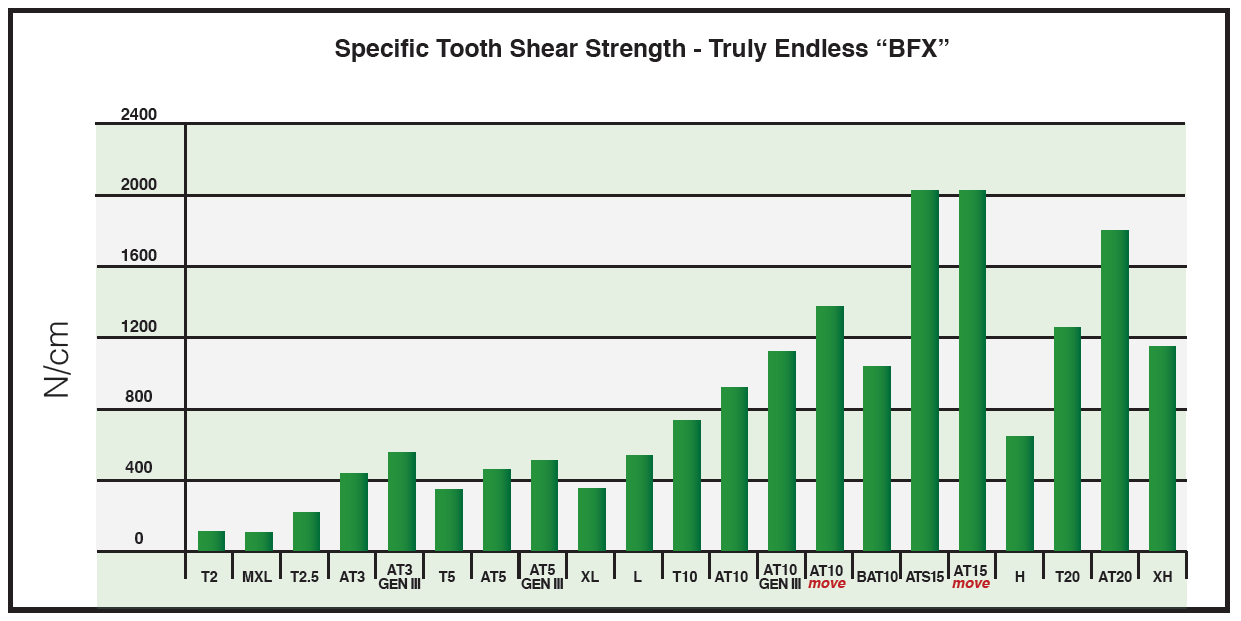

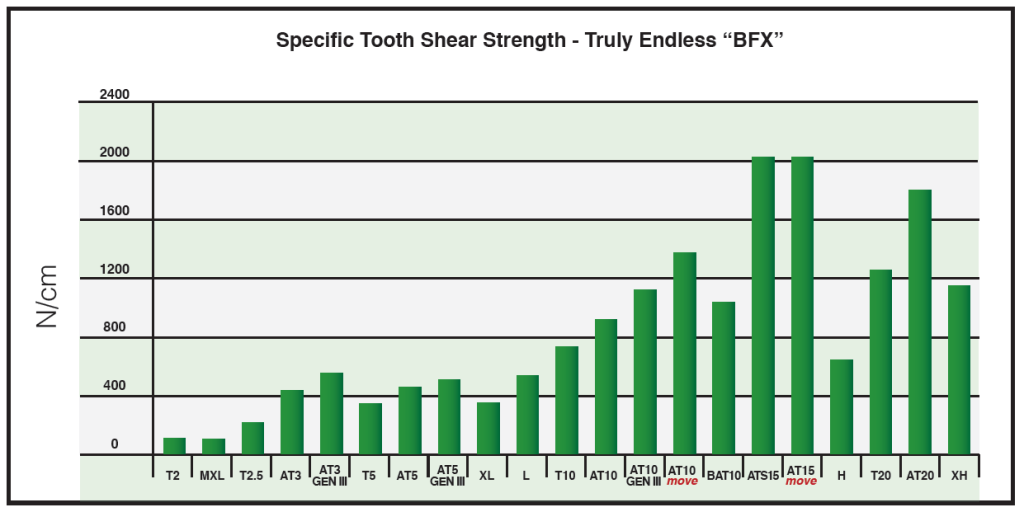

Tooth Shear Strength is the force necessary to permanently deform the tooth or delaminate the tooth from the cable. Specific tooth shear strength depends on the rotational speed. The maximum specific tooth shear strength is the load limit that the belt tooth can bear in continuous operation. You can find these values in the B212 catalog.

Note that adequate tooth shear strength alone is not sufficient, as the belt may still experience tensile failure.

The high specific tooth shear strength of the BRECOflex CO., L.L.C. ATP profile (as an example) is achieved by optimizing its force and load distribution. In this case, the effective force is distributes between the two tooth faces. In the case of AT10MOV, there is a FEA optimized tooth face and a friction reducing coating.

BRECOflex CO., L.L.C. Timing Belt Tooth Shear Strength Chart

See more definitions and formulae used in calculating tooth shear strength as well as helpful conversions charts

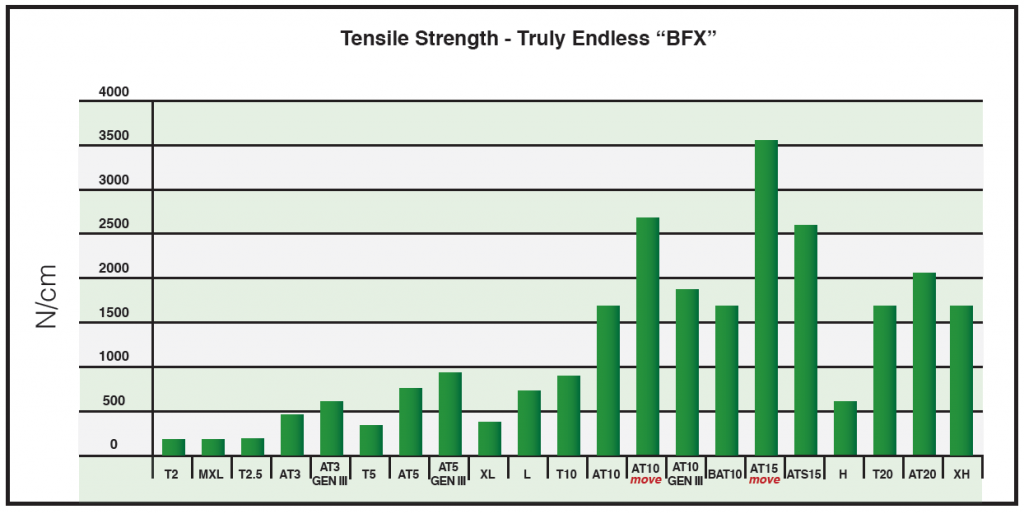

Tension cord tensile strength is the admissible tensile load on a belt cross section. It is also the force required to permanently elongate or break the belt cables. Tension member strength and spring rate is determined by the tension member construction and placement. In the case of BRECOflex timing belts, tension member filaments are helically wound and laid in a bifilar arrangement to achieve a strong and flexible timing belt. Tension member construction also influences the tooth shear strength as well as the power you can transmit.

Tensile Strength of Tension Member (Fzul) is the design strength of the belt. The test break strength, or ultimate tensile strength, is somewhat higher than Fzul. The yield strength is the point at which permanent plastic elongation of the tension members occurs. Important note: always consider the total tension on the belt including pretension, when comparing to the tensile strength.

BRECOflex CO., L.L.C. Timing Belt Tensile Strength Chart

Also paramount to tensile strength is proper pre-tension. Although pretension does not affect tooth shear strength, the pretension and peripheral force together affect the cable tensile strength.

pretension + force transmitted (peripheral) must be less than tensile strength (Fzul)

You can learn more about sizing by using the calculations program or the belt calculations forms

Size to Motor– Easiest method…check motor specs and size.

Why would you use this method? Under a jam or crash condition the motor can apply more power than normally used for operation. Sizing the belt to the application may cause it to break during a jam.

Size to application – A more complex procedure. We must evaluate inertia, friction, weight and any other forces affecting the belt.

Why would you use this method? Because sometimes you may be able to specify a smaller belt, reducing the cost and the mass to be accelerated. Many machines have motors that are a much larger size than they require to do the work. Sometimes the customer has not yet sized a motor and sizing to the application is the only method available.

When sizing and specifying a timing belt for your application, you need to consider many factors. Because some applications require more strength than others, tooth shear strength and tension member strength are vital considerations in determining the timing belt that is right for you. For more assistance you can speak to an application engineer or learn more about our timing belts.